Motto:

The elementary particles accelerated in the CERN's Large Hadron

Collider have many interesting behavior. It is amazing how interesting

can a pencil behave which have a velocity of approximately 200 m/s.

Although its velocity seems to be negligible compared to the velocity

of the hadrons the collision with it can be as inconvinient as it

is in the case of the elementary particles.

Elementary

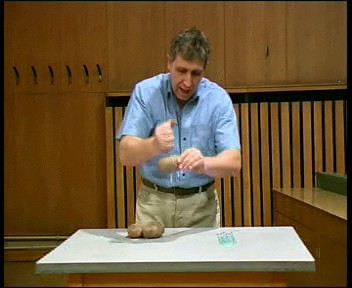

“Pencil Shoot” - potato & staw

A much lower energy version of the

pencil shoot (see below) can be reproduced with soda straws and

potatoes. I will present the experiment in the following way: At first

I show, that it is impossible to push the straw trough the potato

with a slow speed. The successful solution is, that the straw must be

driven at a very high speed so that it will become

able to penetrate the potato. The properties of materials are governed

by state-variables. Such a state-variable is the speed of deformation.

If the speed of deformation exceeds a well-defined threshold then the

straw cuts through the potato unhamperedly. The idea of this experiment

came from an observation of the Nature. Anybody can observe that in

extremely strong wind (tornado, hurricane) small and even soft objects

can cause serius damages. One potato can serve several students in a

group, making this a low-cost experience.

Fastest Surface Wind Speed ever measured:

The fastest surface wind speed at a

low altitude was registered on March 8, 1972 at the USAF base at Thule,

Greenland, when a peak speed of 333 km/h (207 mph) was recorded. (

http://www.guinnessworldrecords.com/)

Real

Pencil Shoot

This demonstration falls into the

category of those whose details are difficult to explain but the

overall effect is quite obvious. Due to the pencil’s shape and a speed

of about 150 m/s, it is capable of transferring its energy due to

motion (kinetic energy) in a rather amazing way. When the pencil

strikes a 2.5cm piece of plywood, the plywood is easily penetrated by

the pencil, with little or no visible damage to the point of the

pencil. Since the plywood is much thinner than the length of the

pencil, and the energy transfer is focused on a very small region of

the plywood, the individual layers or strata of the plywood shatter

rather than breaking the pencil. Wood is very strong under compression,

and since the entire pencil travels as a unit, the forces of collision

act only to compress it. The nature of the collision creates a very

large and sudden shearing force on the layers of plywood, and wood

grains are much easier to break under shearing forces than under

compression.

Equipment:

- 2 kilogram cylinder filled with carbon dioxide at a pressure of

6.2 MPascal. At this pressure, most of the carbon dioxide has

condensed to liquid.

- Ordinary pencil (wooden, hardness HB, sharpened just before the

experiment)

- Wooden board (60 cm by 10 cm by 3 cm)

- 1.5 meter long stainless steel tube (inner diameter 8 mm, wall

thickness 2mm) mounted on a table.

The equipment is displayed to the

audience and then discussed. The pencil is dropped into the stainless

tube held vertically and then the tube is fixed to the table. First the

safety stick is removed for the valve to be possible to open. Then I

squeeze the handle of the gas cylinder quickly. The pencil goes

shooting down the stainless tube and busts through the wooden board!

Explanation

Basic Ideas:

A gas exerts pressure on all sides of

the container which contains the gas. The amount of pressure is related

to the energy of the gas and the amount of gas. The higher the energy,

the more pressure is exerted, and the more gas contained, the more

pressure is exerted. The process is as follows: a short burst of CO2

gas from a fire extinguisher provides enough force to accelerate a

pencil along a length of stainless steel tubing to a velocity

sufficient to allow the pencil to penetrate a piece of wooden board of

3 cm thick.

During the setup, nothing exciting is

happening. The important aspects of this step are to be sure that the

small wooden board is securely fastened inside the joiner’s clip, that

all the tubes are properly connected, and that the stainless steel tube

is aimed at the wooden board. The gas inside the cylinder is being held

under very high pressure. When I squeeze the handle of the cylinder,

some of the gas inside is released. This gas travels through the

flexible tube until it reaches the pencil. The pressure inside the

container becomes so great that there is enough force to shoot the

pencil down the stainless steel tube. The pencil is accelerated so much

that it goes shooting through the small wooden board!

Warning:

This is a potentially lethal demonstration!

All high pressure fittings must be properly connected!

Use only objects and hose that hold high pressure!

Let me take a conclusion of all the above:

- Observation:

e.g.: seeing various interesting phenomena, such as a straw of grass

found penetrated through planks of wooden houses after striking

twisters.

- Experiments:

now, we can repeat this very phenomenon by driving a straw through a

potato or shooting a pencil through a wooden board as described above.

Well, we may choose to repeat these experiments with no further goal,

thus just for the sake of experimenting.

- Application:

so let us move further and do apply all that we have “newly”

discovered, e.g. when it comes to shooting nails into concrete panels.

This

Trinity, Observation (inducing appetite for making) Experiments (which

are the basis for) Application in real life, is the very Heart of the

Science of Physics.

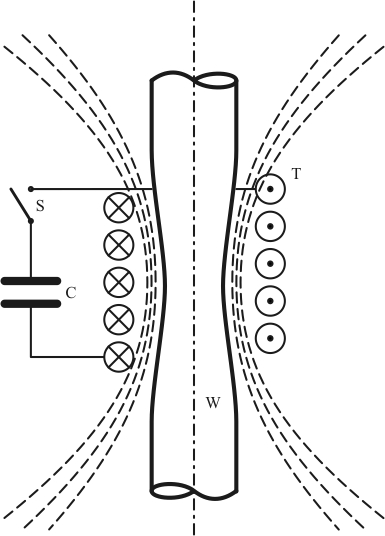

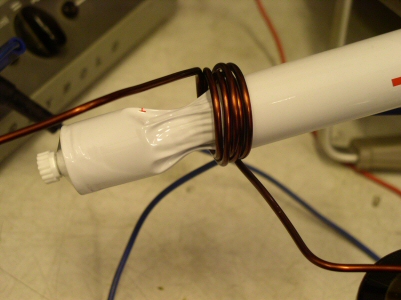

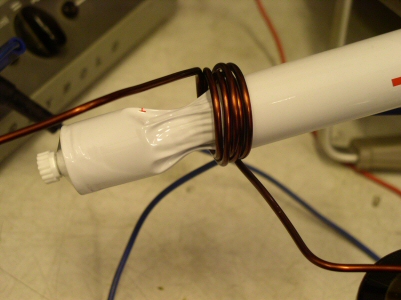

Electromagnetic

metal forming

Electromagnetic metal forming is a high energy

rate cold forming technique which brings to industry an assembly of

components.

The tool operates by electromagnetic pulse and not by mechanical or

hydraulic

means. The forming equipment can be made compact, and easy to operate.

The

principle of the electromagnetic metal forming

The electrical energy stored in

the capacitor (C) is discharged

by high current switch device (S)

and will

establish an impulse current in the coil (T). In our case the current switch

is

a low-cost ,,home-tinkered’’ electromagnetic

relay.

By this impulse

current a

magnetic field is created around the coil. This field includes an eddy

current

in the work piece (W) which has

the same frequency as the impulse current in

the coil. If the frequency is big enough – (from technical reasons it

must be

in the 10 kHz frequency range) – the eddy current is condensed in the

surface

layer of the work piece (skin effect).

From electrotechnical

point of

view the coil and the work piece have a transformer coupling. The coil

is the

primary winding of the transformer and the work piece is considered a

short-circuited secondary single turn coil. According

to the law of induction antiparallel

currents repell each other.

If this force exceeds

the forming

resistance of the metal of the work piece, the plastic deformation of

the work

piece will be resulted. When the work piece (W) is inside the coil (T), then

shrinking deformation if outside then enlargement deformation will

happen.

Of course in practice

there are

more complicated coil-work piece systems than the simplest case in the

figure

but the functional principles are the same.

Advantages of the electromagnetic forming

- The pressure is applied directly to the work

piece through the medium of magnetic field and the forming can be

accomplished

with no physical contacts, consequently no scrapes or scares damage the

surface

of the work piece.

- No moving parts and no lubricants and little

wear of the tooling result low maintenance costs.

- In many cases forming and assembling operations

can be combined in one operation. (e.g. mounting metal fittings

onto the end of a gum tube)

- The easily and quickly changeable forming coil

and field shapers make possible to form and assembly a wide variation

of work

pieces with one forming equipment.

|

|

|

|